Copyright © 2019 All rights reserved Aus-Precast Pty Ltd | Website Created by PCMadness

Client advantages:

Sleepers can be utilized in several ways and in a variety of areas such as:

Hardstands can be used for many applications

Modular precast concrete comes in a variety of forms:

SkidCreteTM – Modular

Patent 2019100619

Aus-precast and Raine Consulting have been working closely together in the research and the development of an innovative new product, purpose build for the mining sector. This is just the beginning of innovative measures we are undertaking within the precast concrete industry. Our aim is to compliment low site interface requirements utilising the upper end of hazard management within the hierarchy of hazard control. By eliminating, substituting and engineering out, we have patented and developed an industry leading product that surpasses current technologies.

Purpose

SkidCrete is an innovation that removes redundant structural steel from a wide range of mechanical equipment skids that house or populate process equipment utilised in a wide array of mining, process, food, fluid management and allied industries. Traditionally equipment is built on skids to allow higher levels of completion and for fabrication and testing to be conducted in metropolitan areas where there is a greater access to skilled labour, manufacturing and engineering resources. Conventionally this equipment has been built of structural steel skid and transported to site for installation on insitu concrete. Thus, the role of the structural steel is redundant once the system gets to site. SkidCrete leverages the wide range of tilt panel technologies coupled with Commercial of the Shelf components (COTS) to realise a functionally equivalent monolithic concrete skid that is fabricated off-site, eliminating most of the structural steel with significant cost advantage.

Design Features

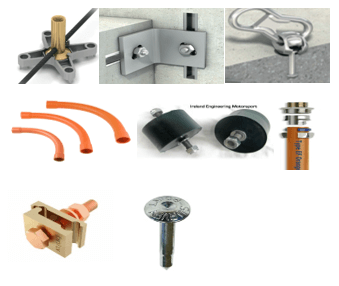

Ferrule Threaded Anchor – The primary device for securing a wide array of process equipment.

Cast in Channel – Cast in Channel provides flexibility for freedom of movement for items in the skids

Lifting Anchor – Precertified with a WLL standardised load range.

Post Tensioning – Large equipment footprints require multiple substrates for logistical reasons. We have a post tensioning method, with guarantee of seal.

Electrical, Earthing and Instrument Feeds – Flush fit, bell end electrical conduit is installed for mechanical footprint requirements.

Motor Mounts – Equipment operating rotational systems require Motor Mounts to absorb destructive frequencies from variable speed drives.

Survey Markers – The skids will be equipped with Survey Markers that will represent set-out points for each skid.

Components

Cyclone Tie Down Blocks come in standard sizing and made to order:

SkidCrete – Shipping

Introducing a series of Shipping Container Foundations that are suitable for all Australian conditions and environments. Aus-Precast has realised a need in the marketplace for an engineered precast concrete foundation that is ready for immediate use.

Purpose

Provide a structurally designed foundation, with off the shelf corner castings, that locks the container in place, coping with the worst load cases arising through AS 1170 Structural Actions. This system eradicates the need for external rigging and due to the flush fit finish; thereby removes all external tripping hazards. This offers significant improvements for workplace KPI’s.

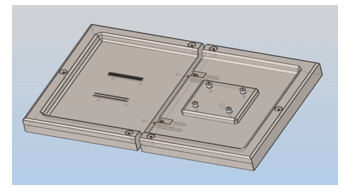

Design Features

Corner Castings, compatible with static shipping. Container twist lock systems. Engineered cast in lifting anchors. Fork tine rebates and heavy-duty concrete mix.

SkidCrete – Shipping

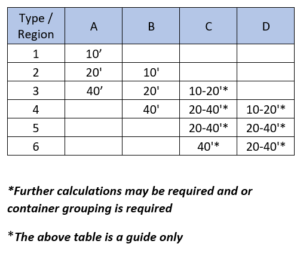

Range

Type 1 – 2440 W x 600 L x 300 H – Weight 1000kg

Type 2 – 2440 W x 1200 L x 300 H – Weight 2125kg

Type 3 – 2440 W x 1200 L x 400 H – Weight 2834kg

Type 4 – 2440 W x 1200 L x 600 H – Weight 4250kg

Type 5 – 2440 W x 1800 L x 600 H – Weight 6376kg

Type 6 – 2440 W x 1800 L x 750 H – Weight 7970kg

MDR Gallery – see pdf attatchment

Talk with us, Aus-Precast understands the demands that business experience today and have the ability to generate ‘value add’ from existing and new products within the precast industry for both non and process infrastructure. In essence, value realisation is about showing the tangible or business value by adjusting traditional methods of construction.

At Aus-Precast, B2B relationships means, providing a technical service and a high level of customer support during field visits and or dispatch is inherent of beneficial outcomes, this is critical to future growth within the precast concrete industry. Diagnostic errors or technical problems? Determining proper solutions are key to success.